AMEOLI offers precise CNC machining within the scope of lathing, milling in 4 axis and cutting.

CNC machining advantages

The combination of extraordinary precision and a modern control system results in more efficient and accurate processing of materials. The device analyses a few factors at the same time. It takes into account the type of the material, its roughness, as well as the expectations of the client. Designed in advance, the whole process is automated and computerized, which ensures stability and repeatability of the elements.

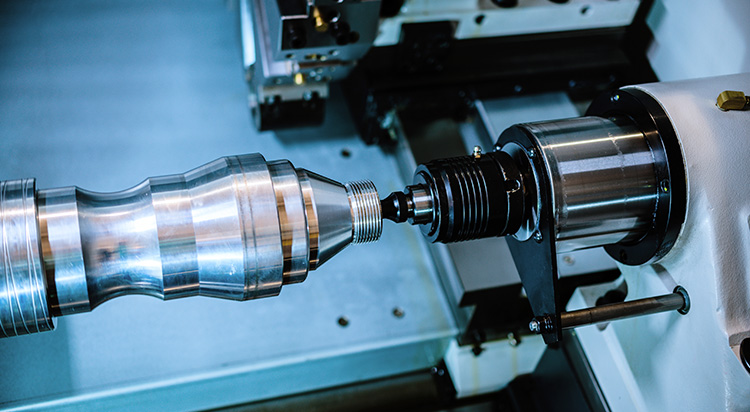

Lathing

We use specialist machines and employ qualified workers, so that we can offer OD turning, shape turning, grooving, cutting, drilling, threading and frontal processing.

Maximum dimensions of the semi-finished product:

- Diameter above the lathe bed 620mm

- Diameter above the carriage 320mm

- Maximum length of the element 1500/2000mm

- We process synthetic materials, steel, stainless steel, non-ferrous metals

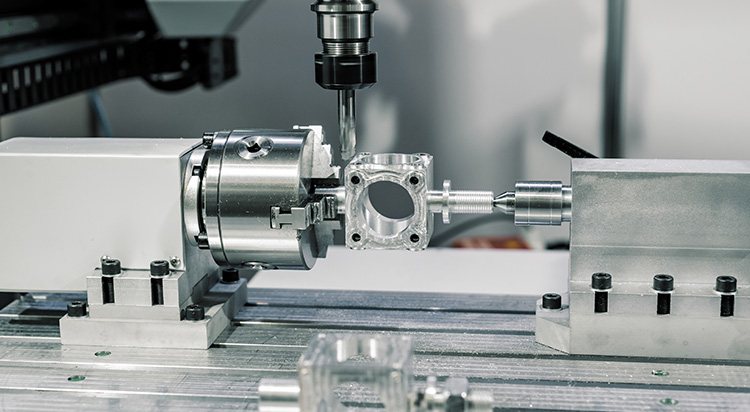

Milling

Modern machinery and qualified staff are key elements that allow us to execute the most complicated assignments. We use BLUM measuring probes, that enable us to perform details with the highest accuracy (up to 3 micrones).

Maximum feed:

- Axis X (table) 1300 mm

- Axis Y (saddle) 670 mm

- Axis Z (spindle) 625 mm

12 000 turns per minute (with interial spiral cooling)

THD 200mm dividing head enabling 4-axis work

Cutting/milling-cutting ploter

Our ten-year experience in the field of cutting various types of gaskets allows us to meet the expectations of even the most demanding clients.

Maximum feed:

- Axis X 2150 mm

- Axis Y 3650 mm

- Axis Z 200mm

Spindle 22 000 turns/min

Programming

A typical process of computerized production consists of computer-aided design (CAD), computer-aided manufacturing (CAM) and the execution (CNC). We use the following programs:

- CAD – Solid Works

- CAM - Edge Cam

- CNC – fanuc, sinumeric

Are you looking for reliable and innovative solutions for your manufacturing?

Contact us to see how we can improve your production systems.